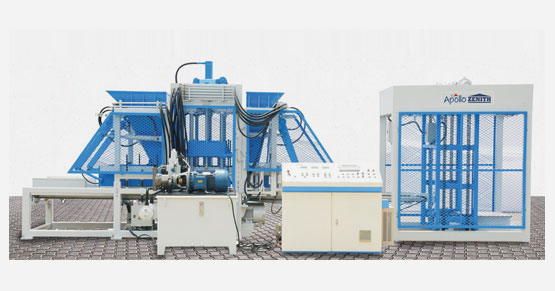

Concrete Block Making Machines by Leading Manufacturer & Supplier in India

These German designed Zenith machines are most versatile, manufactured in India with SIEMENS frequency control technology for producing Hollow & Solid Blocks, Pavers, Kerbstones, Flyash Bricks etc. These are ideal & economical solutions for initial start-up. Investing in a high-quality blocks making machine ensures precision, efficiency, and durability in concrete block production.

Core Technology of Concrete Block making machine

Frequency conversional control technology

This energy saving technology was re-innovated and improved by Germany R&D center. It can save 20% – 40% power by adjusting the frequency converter, compared to traditional motor; at the same time, it can greatly improve the quality of concrete products and prolong the motor lifetime. An advanced block machine with frequency conversional control technology enables manufacturers to enhance production speed while minimizing energy consumption.

High – efficient Hydraulic System

The hydraulic pump & valve are from international brand. Adopt high – dynamic proportional valve and constant output pump to adjust the oil speed & pressure, with the features of high – stability, high – efficiency and energy – saving. For large-scale production, a paver block machine equipped with a high-efficient hydraulic system is essential for achieving consistent product quality.

Fully – automatic Control

Perfectly combine the automation technology and system from Germany. The automatic control is of easy operation, low failure ratio and high reliability. A fully automatic concrete block making machine reduces labor costs and ensures seamless production with minimal errors.

Compulsory Feeding

Uses two SEW feeding motors, which control two mixing shafts. The feeding frame, bottom plate & mixing blades are made of high – duty HARDOX steel, which strengthens the sealing performance and prevent the material leakage. The discharging gate is controlled by SEW motor. Manufacturers looking for a high-performance concrete block machine must consider models that incorporate advanced compulsory feeding technology for uniform concrete mixing.

Heavy Duty Structure and wear resistance Moulds

Heavy duty structure and wear resistance moulds adopts CNC & Wire Cutting to Make sure paver size accuracy. Carbon-dioxide welding for crack resistance with heat treatment and carburization, sand blasting and other machining Process. It becomes more robust and resistant to the frequent & strong vibrations. The use of premium-quality materials in cement block making machine components extends the lifespan and improves output efficiency.

High – efficient Vibration

Adopt the most – advanced vibration technology from Germany. The vibration table consists of dynamic table & static table, which greatly improves the vibration efficiency and guarantees the high quality of concrete products. A solid block making machine with high-efficient vibration technology ensures precise molding and structural integrity of the final product.